Hiring and keeping employees that were required to handle and stack heavy bags and boxes, day in and day out, was a challenge for GHF. Automating this process was challenging due to the high-production rates and unique package sizes. In addition, some products had to be loaded into totes, which made it difficult to use typical end-of-arm tools in this confined space.

Our Products

We design and build end-to-end solutions – from small, stand alone palletizing cells to large scale, fully integrated, multi-robot automation and distribution systems. With over 2000 palletizing and de-palletizing systems installed around the world across a wide range of industries, we understand that the devil is in the detail. Our comprehensive in-house design and manufacturing capabilities allow us to create and execute the best solution for any application.

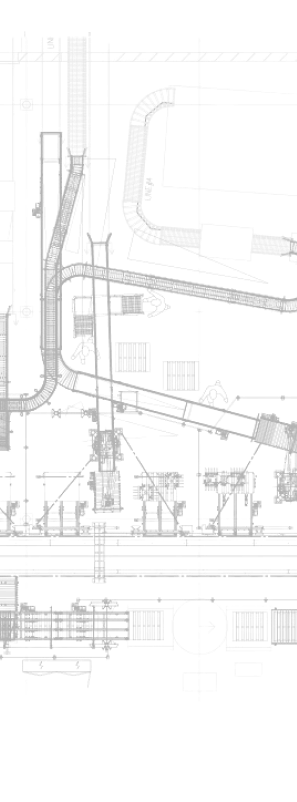

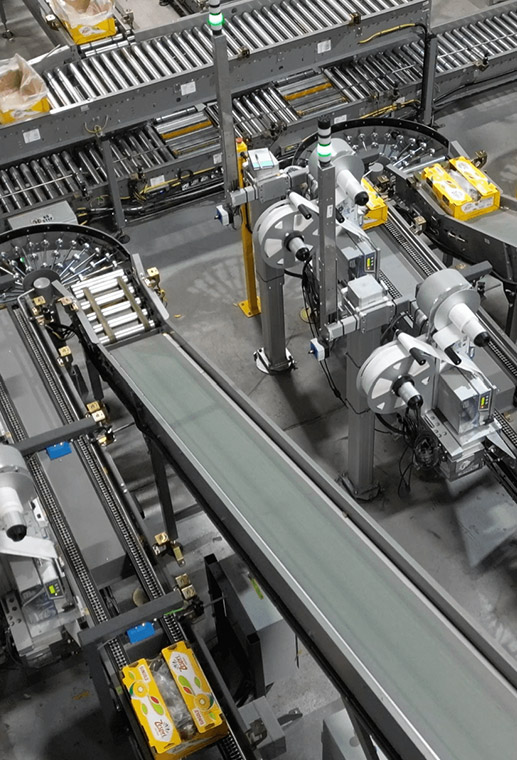

01 Product Conveying

We craft intelligent solutions tailored precisely to match your unique SKU specifications and product handling requirements. The array of possibilities is boundless, ranging from various belt and modular conveyor options to product gap mapping, transfer alternatives, layer forming techniques, zoned zero pressure accumulation and case elevators—encompassing every cutting-edge capability available in the market.

Learn More

02 Custom End-of-Arm Tooling

Every one of our End Of Arm Tools is custom designed and manufactured in-house, allowing our extensive programing and support team to offer unparalleled flexibility and performance. We focus on robot path and sequencing efficiencies to maximize repeatable product transfer rates, as well as custom dynamic stack pattern software which simplifies the addition of new SKUs.

Our exclusive partnership with Kawasaki Robots allows us preferred integrator status and immediate access to manufacturer technical support.

Learn More

Our exclusive partnership with Kawasaki Robots allows us preferred integrator status and immediate access to manufacturer technical support.

03 Robots

We are a distributor partner of Kawasaki Robots and part of the Kawasaki Preferred Integrator Network. With thousands of robots installed around the globe, we have integrated more Kawasaki palletizing robots than any other company in the world.

We have extensive in-house robot and programming knowledge that is unmatched in the industry. Our system and robotic excellence won us numerous Partner awards from Kawasaki Robotics, and a prestigious Supplier of the Year from PepsiCo.

Learn More

We have extensive in-house robot and programming knowledge that is unmatched in the industry. Our system and robotic excellence won us numerous Partner awards from Kawasaki Robotics, and a prestigious Supplier of the Year from PepsiCo.

04 Pallet Handling

Customized to suit site layout and precision-engineered for optimal weight distribution and pallet dimensions. We incorporate chain, roller, and belt conveyor options, enabling the seamless handling of multiple pallet types on single lanes. We design and manufacture automatic pallet dispensers, lifters, elevators, turntables and high-speed trolleys to facilitate smooth, reliable pallet transfers throughout the system.

Every element is seamlessly integrated with sensors, motors and controls, ensuring functionality and safety. From aluminum covers, enhancing plant hygiene to full walk-over conveyor access for operators, our systems are designed for efficiency and durability.

Learn More

Every element is seamlessly integrated with sensors, motors and controls, ensuring functionality and safety. From aluminum covers, enhancing plant hygiene to full walk-over conveyor access for operators, our systems are designed for efficiency and durability.

05 Stretch Wrapping

With over five decades of expertise in designing and manufacturing stretch wrappers, our commitment to excellence is ingrained in every detail.

Customized SKU wrapping, integrated folding choices for both base cap and top cap, specialized split wrapping for multi-layer pallet configurations, and the precision of robotic corner board application, opens up limitless possibilities.

Our cutting-edge systems are characterized by seamless PLC and HMI control, sophisticated safety zone interfacing, a selection of turntable and orbital options as well as multiple pallet size capability.

Learn More

Customized SKU wrapping, integrated folding choices for both base cap and top cap, specialized split wrapping for multi-layer pallet configurations, and the precision of robotic corner board application, opens up limitless possibilities.

Our cutting-edge systems are characterized by seamless PLC and HMI control, sophisticated safety zone interfacing, a selection of turntable and orbital options as well as multiple pallet size capability.

06 Electrical, Automation and Safety

As a UL-certified custom panel builder, safety is our top priority. Our PLC and HMI logic capabilities are built with application-specific safety hardware integration.

Our independent safety systems are seamlessly integrated into the Controls and HMI architecture, creating a logical and intuitive environment for system operators. This integration ensures a user-friendly experience while maintaining the highest standards of safety and efficiency.

Learn More

Our independent safety systems are seamlessly integrated into the Controls and HMI architecture, creating a logical and intuitive environment for system operators. This integration ensures a user-friendly experience while maintaining the highest standards of safety and efficiency.