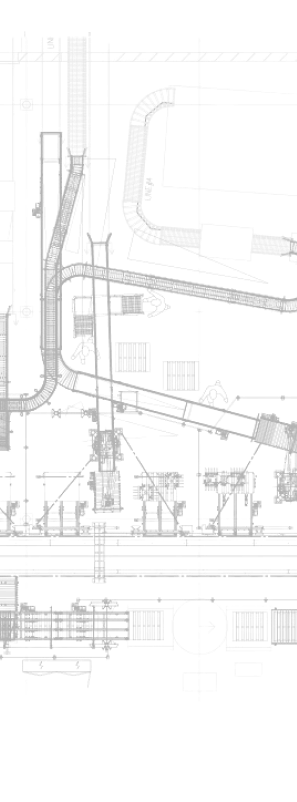

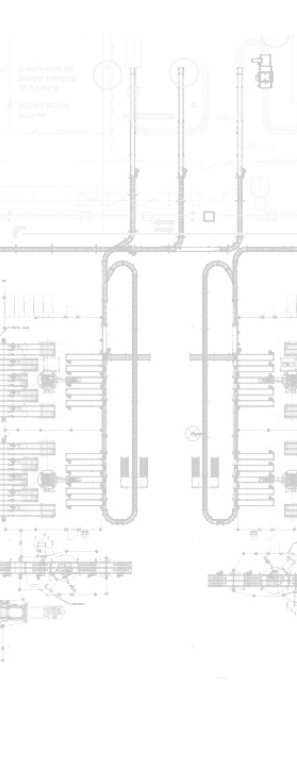

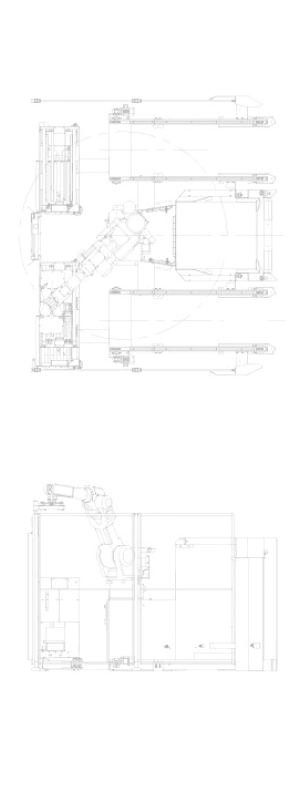

Hiring and keeping employees that were required to handle and stack heavy bags and boxes, day in and day out, was a challenge for GHF. Automating this process was challenging due to the high-production rates and unique package sizes. In addition, some products had to be loaded into totes, which made it difficult to use typical end-of-arm tools in this confined space.